| Standard | Odor reduction | Fire safety | Energy recovery | Safety in the work | Noise regulation | Duct cleaning | About ozone | Data sheet |

Knowledge base – Kitchen exhaust

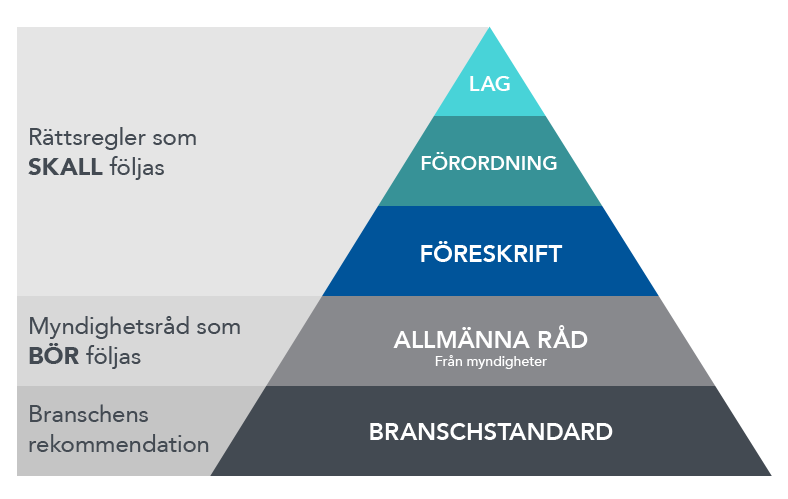

Industry Regulations

Read more about fire safety according to Boverket’s Building regulations, BBR, Fire safety

- Class 1A – For all types of cooking

- Class 1B – With fire extinguishing system

- Class 2A – For food heating kitchens etc.

- Class 2B – With built-in purification

- Class 3 – Residential and office buildings

It is always the planner who is responsible for the facility’s design and function and must, in consultation with the client and possibly the user, choose the appropriate flue channel design based on what is needed for the intended operation. The planner should consider which activities are suitable in the premises, and also what changes to the activities on the premises that are possible. Examine whether there is space for fan rooms and ventilation installations throughout the building, including exhaust air ducts. It is also suitable to take into account that a change in the operation only requires small interventions in the ventilation system and in the building in general. In addition, the planner should find out what type of organization exists around the restaurant business, as some installation components need continuous maintenance to sustain the intended function. The following classifications are a way of realizing different solutions that the industry considers reasonable. These are not to be considered definitive and do not deprive the planner of their responsibility.

CLASS 1A – For all types of cooking

Ducts that are grease fire resistant that have passed tests in accordance with ISO 6944-2, for cooking on ovens that combusts solid, liquid or gaseous fuels and for all other types of cooking. As an alternative to completed testing, the channel, when built, can be implemented according to instructions in chapter 5 in Imkanal 2012:2.

CLASS 1B – With fire extinguishing system

Fire-resistant ducts that are provided internally throughout their length with a fire extinguishing system with sufficient capacity, taking into account the fire load in the deposits in the duct, limiting the risk of fire in the deposits inside the duct being spread through or outside the duct system.

| Class | 1A – Combustion of solid and liquid fuel | 1A – electricity and gas operation | 1B |

| Application | Optional kitchen equipment for all types of cooking, including charcoal grills and wood stoves. | Optional kitchen utensils, except such equipment that is powered by solid or liquid fuels, such as charcoal grills and wood stoves. | Optional kitchen equipment powered by electricity or gas if the duct system is provided with an internal fire extinguishing system. |

| Limitations | Operations can be changed without affecting the level of fire protection. | Operations can be changed without affecting the level of fire protection. However, it is not allowed to connect charcoal grills or wood stoves. | It is not allowed to connect charcoal grills or wood stoves. |

| Exhaust placement | The exhaust air should exit 1.0 m above the roof covering and the roof ridge. | The exhaust air should exit 300 mm above the roof covering. | The exhaust air should exit 300 mm above the roof covering. |

| Protection against fire spread inside kitchen/fire cell | EI60 insulation. Fire protection distance of 50 mm | Uninsulated (E60) Fire protection distance of 100 mm | Uninsulated (E60) Fire protection distance of 100 mm |

| Protection against fire spread outside kitchen/fire cell | EI60 isolation. Fire protection distance of 50 mm | EI30 or EI60 insulation. Fire protection distance of 50 mm |

|

| Suspension | Corresponding fire engineering class and fire cell class. | Corresponding fire engineering class and fire cell class. | |

| Connection to other channels | Other channels may not be connected to the system | Other channels may be connected to the system. However, cleaning must not be obstructed. | |

| Heat recovery | The system may not be connected to heat recovery. | The system can be connected to heat recovery. However, consider fire or functional risk. | The system can be connected to heat recovery. However, consider fire or functional risk. |

| Fire or smoke dampers | May not be used. | May not be used. | |

| Density | Density class C, as well as liquid-tight design. | Density class C, as well as liquid-tight design. | |

| Cleaning | Wet cleaning technique | Wet cleaning technique | |

| Material requirements | Stainless steel | Optional galvanized, black plate or stainless steel | |

| Insulation | Class A2-s1, d0, without through-joints. | Class A2-s1, d0, without through-joints. | |

| Joining | Bolted flanged joints, or according to the manufacturer’s instructions. | Pop rivet, metal screw, guide joint or similar. | |

CLASS 2A – For heating kitchens etc.

Fire-resistant ducts for commercial kitchens where the cooking itself leads to low flammable coatings inside the duct, for example, kitchens that are only used for heating, boiling, and kitchens that are only used to a limited extent, for instance only occasional.

CLASS 2B – With built-in cleaning

Fire-resistant ducts for commercial kitchens where filtering systems, for example using UV light or ozone cleaning technology, effectively reduces the risk of combustible deposits being formed in the duct system. As filtering systems, fat filters are not included in the classification of the channel.

CLASS 3 – Residential and office buildings etc.

Fire-resistant ducts for cooking on household stoves in homes, offices and workplaces intended for activities other than dining.

| Class | 2a | 2b | 3 |

| Application | Electric pizza ovens, bakery ovens, bake off ovens, hot-air ovens, infra grills, kebab grills, heating kitchens, cooking pots and so on. Educational kitchens. Intermittent cooking in cafes and similar. | Optional kitchen equipment powered by electricity or gas provided that a UV light, ozone cleaning system or similar is installed. | Cooking in household stoves in homes, offices and workplaces. |

| Limitations | It is not allowed to install catering equipment for cooking according to class 1A, 1B or 2B. | It is not allowed to install coal grills or wood stoves. | It is not allowed to install catering equipment for cooking according to classes 1A, 1B, 2A or 2B. |

| Exhaust placement | The exhaust air should open 300 mm above the roof covering. | The exhaust air can be placed in a suitable place in terms of fire and hygiene safety. | The exhaust air can be placed in a suitable place in terms of fire and hygiene safety. |

| Protection against fire spread inside kitchen/fire cell | Uninsulated (E60) Fire protection distance 100 mm | Uninsulated (E60) Fire protection distance 100 mm | Uninsulated (E15) Fire protection distance 30 mm |

| Protection against fire spread outside kitchen/fire cell | EI30 or EI60 insulation. | EI30 or EI60 insulation. | EI15, EI30 or EI60 insulation. |

| Suspension | Corresponding fire engineering class and fire cell class. | Corresponding fire engineering class and fire cell class. | Corresponding fire engineering class and fire cell class. |

| Connection to other channels | Other channels may be connected to the system. However, cleaning must not be obstructed. | Other channels may be connected to the system. However, cleaning must not be obstructed. | The channel may be included in another system. |

| Heat recovery | The system can be connected to heat recovery. However, consider fire hazard or functional risk. | The system can be connected to heat recovery. However, consider fire hazard or functional risk. In the case of UV/ozone, there must be no risk of air transfer. | The system can be connected to heat recovery. |

| Fire or smoke dampers | May be used. | May be used. | May be used. |

| Density | Density class C. | Density class C. | Density class C. |

| Cleaning | Dry cleaning technique | Dry cleaning technique | Dry cleaning technique |

| Material requirements | Optional galvanized, black plate or stainless steel. | Optional galvanized, black plate or stainless steel. Stainless steel is recommended for parts exposed to high ozone concentrations. | Optional galvanized, black plate or stainless steel. |

| Insulation | Class A2-s1, d0, without through-joints. | Class A2-s1, d0, without through-joints. | Class A2-s1, d0, without through-joints. |

| Joining | Pop rivet, metal screw, guide joint or similar. | Pop rivet, metal screw, guide joint or similar. | Pop rivet, metal screw, guide joint or similar. |

The information presented above is industry recommendations in Sweden and is meant to show an example of how regulations and recommendations can be designed. Some aspects need to be followed by Swedish law, and some are recommendations. Look into what the rules and recommendation apply in your country.

Odor reduction – Less disturbing cooking odors

In addition to increased fire protection and efficient energy recovery, odor reduction is one of the main reasons for using ozone-based air purification.

- Continuous and reliable purification of air with ozone reduces the emission of cooking fumes considerably. This, in turn, reduces the possible risk of complaints from neighbors who may be disturbed by the smell.

-

Requirements for odor reduction are much greater if the exhaust duct is positioned close to residential buildings. In these cases, a final carbon filter should be considered.

In urban areas, ozone purification of exhaust air can be the difference between obtaining permission or not for running a restaurant business.

Fire safety – Safer commercial kitchens

A direct consequence of ozone purification of a kitchen exhaust air is that grease is reduced as well as increased fire safety due to less grease deposits in the kitchen flue.

With a built-in exhaust air cleaning system, you reduce the fire hazard and may, depending on the local fire code, use less costly channel materials in the installation. At the same time, it reduces the need for duct cleaning since the ducts will be much cleaner.

Reduced Fire Hazard with Ozone Treatment

Three things are needed for a fire to occur; fuel, air and heat. All three factors are present in a hood/exhaust duct filled with fatty high energy air above e.g. woks, deep fryers and frying table. Remove one factor and the fire hazard is reduced.

Ozone is effective in reducing fat in the kitchen flue. This prevents the build-up of energy-dense, fire-prone fatty deposits in the ventilation duct and minimizes the fire hazard.

Extinguishing System

Fire extinguishing system with a liquid extinguishing agent can be installed in kitchen hoods and protects the staff and further reduces the risk of an open flame developing into a fire.

Regular Supervision

With a built-in exhaust air cleaning system, you reduce the fire hazard to fire safety class 2B according to IMKANAL 2012 and might, depending on the local fire

code, use less costly channel materials in the installation. At the same time, it reduces the need for duct cleaning since the channels will be much cleaner.

The frequency which a canal must be inspected and cleaned must be decided from case to case.

Energy recovery

Energy efficiency is achieved through a combination of measures and, according to studies, those affecting the ventilation have the greatest impact:

-

- Technology in the kitchen

-

- Choose energy efficient equipment and machinery

- Use equipment that allows for Demand Control

-

- Technology in the kitchen

-

- Ventilation

-

- Use Demand Control Ventilation

-

- Purify the exhaust air (read more about Treating exhaust air in commercial kitchens

- Utilize heat recovery from purified exhaust air

-

- Ventilation

-

- Cooling

-

- Efficient refrigerators, freezers, etc.

- Replace cooling of e.g. garbage rooms with other technologies

-

- Cooling

-

- Maintenance

- Regular equipment maintenance helps to maintain high efficiency and thus lower power consumption

- Maintenance

- Staff training

-

Utbilda peEducate the staff! The way the kitchen staff use the equipment has a major impact on the energy consumption.

-

Studies show that the greatest savings potential is in these areas, where measures for the ventilation are by far the most important.

Safety in the work environment

In addition to the fact that fire safety increases, as discussed above, there are some additional factors that should be considered in conjunction with ozone and equipment in the kitchen environment:

- Safety – Ozone Sensors

- Noise Requirements

- Duct Cleaning

Safety Precautions

Ozone is a powerful air purifier that must be handled with respect and responsibility. We always recommend that ozone installations are fitted with pressure switches and ozone sensors (ozone monitor):

-

- Pressure Switch

-

- Control the operation of your ozone generator/ozone system with a pressure switch

-

- The pressure switch shuts off the ozone system if the exhaust fan is not in operation (i.e. no flow/pressure)

-

- The ozone generator cannot start if the fan does not generate an airflow

- Another option is to control the ozone system via the ventilation fan

-

- Pressure Switch

- Ozone Sensor (ozone monitor)

-

- Ozone sensors measure the ozone concentration continuously in the surrounding air

-

- Ozone sensors turn off the ozone system in case of levels exceeding allowed limits for ozone

- Read more about Ozone Sensors

-

These preventive measures will help to protect the staff against ozone exposure in case of malfunction.

An ozone sensor is preferably placed in the kitchen as well as at the place where the ozone equipment is located if not placed in the kitchen. This is especially important if the equipment is located where it might be exposed to external impact.

More about Ozone Sensors and Ozone Measurement

There are two different types of measurement techniques for ozone; Either UV photometers, which costs 5 000 euros or more or a semiconductor technology available from less than hundred euros up to 2 500 euros.

We have chosen to use products with a level that we believe provides the accuracy, reliability, and security required.

The type of sensor that we recommend to caterers and commercial kitchens are based on semiconductor technology combined with a patented method, called GSS, providing excellent reliability and safe operation. The special technique used makes the sensor very precise and in many cases comparable to the UV technique. Therefore, they can be used in many cases where you want a safe and reliable measurement but where a UV photometer is simply too expensive.

It is important to know what technology the sensor manufacturer uses and also how their instruments are calibrated. When it comes to measurements in the low range, as for occupational exposure limits specified in local regulations for safety at the workplace, it is important that the sensor is calibrated for that span and that the calibration is NIST-traceable. Traceability is designed to ensure that you use the correct reference points. It is also important that each sensor is supplied with a calibration certificate because each measuring instrument must be checked and calibrated separately.

Another important aspect is the quality of the sensor; for how long does it show correct readings? Many manufacturers nowadays offer very inexpensive sensors which may seem attractive at first glance. However, this can be a dangerous saving because it is impossible to say for how long the sensor element detects correct values.

The risks associated with an inadequate sensor can have serious consequences since the main aim is to ensure a safe and secure work environment. A sensor that does not measure up, technically or in quality, will be the weak link in your safety systems.

The most fundamental questions that each supplier of measuring instruments and sensors should be able to offer/answer are:

- Individual calibration certificate per module

- NIST-traceability, against which reference and how often the reference is calibrated

- Operating time

- Comparison with the reference technology (usually UV)

- How do you notice when it is time to replace elements or recalibrate?

-

Is it an active or passive measurement? How is the baseline value ensured at each measurement?

- Response time

Noise regulation in public areas

According to recommendations from e.g. the Swedish Work Environment Authority, the sound level of equipment for use in commercial kitchens and restaurants should not exceed 50 dBA in order to maintain a good working environment for the staff.

Both our ICT- and FTX- series meet the requirements of <50 dBA. This is not the case for all manufacturers; some similar units display noise levels of 70 dBA and above.

There are good reasons why the regulations have implemented audio requirements (noise requirements) for the workplace. Effects such as fatigue, irritability, accidents and stress can be linked to noise exposure. Monotonous and low-frequency sounds, even at moderate levels, have a negative impact on people in the premises.

Example of noise regulations:

- 70 dB(A) – Conversations with a loud voice can barely be held at a 1 m distance from other people with perfect hearing

- 55 dB(A) – The environment required for effective voice communication in a normal voice in close proximity from the speaker

- 50 dB(A) – The environment required for effective voice communication in a normal voice at 5 -10 m (15-30 ft) from the speaker

Noise Regulation for Indoor spaces*

For more detailed information, contact your local Work Environment Authority.

Maximum noise level: The stated values must be attained in all zones frequented by people, but not closer than 1 m from the noise source. The values indoor are valid at 10 m2 equivalent absorption area. A 5 dB higher level is allowed for occasional sound impulses.

| Type of Area | Maximum sound level LA (dB) at 10 m2 absorption |

| Daycare facilities (common areas, group rooms etc) | 30 dBA |

| Malls | 35 dBA |

| Dining rooms | 35 dBA |

| Offices | 35 dBA |

| Staff rooms, hallways etc | 35 dBA |

|

Toilets, supply rooms etc |

40 dBA |

| Commercial kitchens, garbage rooms | 50 dBA |

* Examples and noise levels are based on Swedish Work Environment Authorities recommendations according to AFS 2005:16.

Duct cleaning

The ventilation system in a kitchen serves to dissipate heat, moisture, fat, cooking fumes and to provide a fresh air supply.

Fat (fumes) is the number one enemy in a restaurant kitchen. Grease is flammable, burns at high temperatures and can lead to large fires which are difficult to extinguish. Consequently, all exhaust ducts in restaurants and commercial kitchens are regularly cleaned.

The duct cleaning process depends on the system. Typically the duct, fan and ventilation unit is sprayed with hot water and grease solvent to remove flammable fat deposits.

The cleaning interval of exhaust ducts is determined by the local municipality and is usually regulated by the safety / fire code in order to prevent chimney and kitchen flue fires.

What does the law say about duct cleaning?*

In Sweden, there are laws about duct cleaning. These laws exist to prevent accidents connected to blocked chimneys. The municipalities in Sweden are responsible for ensuring that the cleaning activities are carried out in accordance with the laws. The municipalities are also responsible for informing how often the chimneys should be cleaned, and this may differ between municipalities. Duct cleaning and fire protection control used to be done at the same time, but have now been separated into two activities at different times.

The Swedish Civil Contingencies Agency (MSB) is responsible to inform how the fire protection control should be conducted, as well as eligibility requirements for the people who are doing the control. Municipalities may decide on fire protection controls in addition to MSB’s regulations, for example checking if damage has occurred in conjunction with duct cleaning or if they suspect other fire technical deficiencies.

Fan systems (ducts) from kitchens in residential buildings no longer need to be cleaned or fire protection controlled. Ducts and channels in restaurants and commercial kitchens are still covered. The property owner can have the right to do the duct cleaning privately. However, fire protection controls need to be done by eligible personnel.

*The laws and rules presented above apply in Sweden and are meant to show an example of how duct cleaning and fire protection controls can be regulated in a country. The information above may not be applicable to your country. Therefore, look into the laws and regulations that apply in your country.

About ozone

Download information about ozone as pdf

Why Use Ozone in Commercial Kitchen?

- Ozone efficiently removes grease and odors

- It treats the entire duct length quickly and cost-efficiently

- Easy to install and operate

Ozone can be regarded as a pair of chemical scissors; an effective pair of scissors that rapidly “cuts” long unwanted grease and odor molecules.

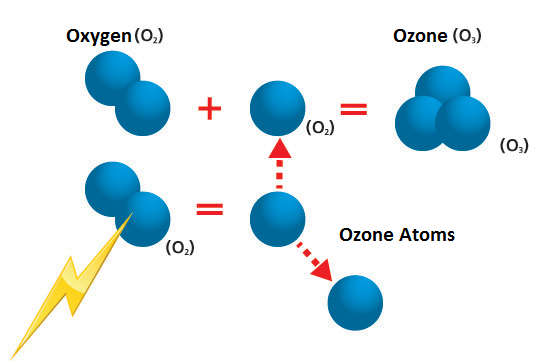

What is ozone?

Ozone is a powerful oxidizing agent. It is soluble in water with a very good ability to eliminate microorganisms, grease and pollutants. Ozone reacts with other substances in its surrounding and it is this characteristic that we use in our systems.

When an ozone molecule collides with another substance, such as odors, it breaks it down into smaller components which are less prone to cause problems. The by-products after this reaction are usually carbon dioxide, water and dust. Ozone that is not used during the process reverts back to regular oxygen.

Ozone also has the ability to eliminate microorganisms such as bacteria and viruses. A reaction between ozone and bacteria damages the cell structure and causes the microbiological activity to cease.

How is Ozone Produced?

Ozone occurs naturally in our environment and in the air. It is formed when oxygen, consisting of two oxygen atoms, is subjected to energy from lightning or UV rays.

These processes are mimicked in purification systems using ozone by allowing oxygen atoms to pass an electric field (corona discharge) or UV light and the ozone is then directed to the treatment area.

The method to produce ozone differs between manufacturers. Read more about our technology.

Ozone Production

To produce small amounts of ozone for a short while is easy. An electric spark in the air is enough. The challenge lies in keeping a constant ozone production for several years. If the flow over the ozone element isn’t completely clean, pollutants are rapidly formed which decrease the ozone production. Picture an engine stalling due to soot build up.

If you are about to choose an air purification system, it is important to know that the method used to produce ozone plays a huge role in the final result – measured over several years. Factors that affect the concentration and the amount of ozone produced are:

Factors that affect the concentration and the amount of ozone produced are:

- The amount and concentration of oxygen that passes over the ozone elements – the more, the better

- Pressure – the higher, the better

- Temperature – the lower, the better

- The design of the electric field

- The way ozone elements are linked together – parallel are beneficial / in series are detrimental

Factors that affect the lifespan of the equipment are:

- Oxygen purity over the ozone elements

- Nitrogen content of ozone elements

- The environment and the purity in which ozone is formed

- Humidity in the supply air or oxygen

- Cooling of ozone elements and electronics

- The right material in the machine

Read more about the 20 things to consider to succeed.

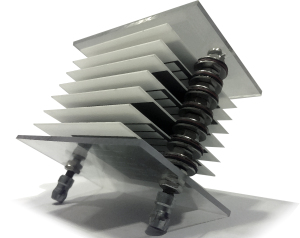

Ozone is formed from oxygen passing through a high voltage field. Efficient cooling is a key design parameter.

Oxygen Source

The oxygen source is very important for how “clean” the produced ozone is. Or rather, how free from unwanted byproducts the gas is.

If the oxygen source for ozone production is ambient air, it will contain approximately 78% nitrogen and water vapor.

However, if an oxygen generator is used the oxygen source will be 93% oxygen, 7% nitrogen and completely dry. This minimizes problems with nitrous acid (formed by nitrogen oxide and water vapor) and ammonium nitrate.

Cooling

The cooling is central to the system’s efficiency, size and reliability. A cooler environment leads to a better ozone production and better environment for the electronics. Unfortunately, it is inevitable that heat is produced in the ozone production process. The heat must be dissipated to avoid reduced ozone production or any possible overheating.

Material safety data sheet – Ozone (O3)

Download Safety Datasheet as pdf

General Data

| Material | Ozone |

| Molecular formula | O3 |

| Principal characteristics | Oxidizing gas – CAS no. 10028-15-6 / EG no. 233-069-2 |

| Molecular weight | 48.0 |

| Production | Corona discharge |

| Content ratio | Up to 18 % by weight in oxygen/oxygen-enriched air |

| Boiling point | -111.0°C |

| Melting point | -192.7°C |

| Solubility in water by weight (at 20°C) | 0.003 g/l (3 ppm) |

| Vapor density | 1.6 (1 = air) |

| Appearance and odor | Ozone is colorless at all concentrations occuring in the industry. It has a pungent characteristics odor usually associated with electrical sparks. The odor is generally detectable by the human nose at concentrations of 0.02 and 0.05 ppm. |

| Fire / Explosion hazard | Ozone is a powerful oxidizing agent. Oxidation with ozone evolves more heat and usually ignites at a lower temperature than oxidizing with oxygen. Ozone reacts with non-saturated organic compounds to produce ozonides, which are unstable and may decompose with explosive violence. Ozone is an unstable gas that, at normal temperatures, decomposes to diatomic oxygen. At elevated temperatures and in presence of certain catalysts such as hydrogen, iron, copper and chromium, this decomposition may be explosive. |

| Flash point | Not applicable |

| Auto ignition temperature | Not applicable |

| Combustibility | Non combustible / favors combustion |

Reaction Data

| Conditions contributing to instability | Ozone spontaneously decomposes under all ordinary conditions, so that is not normally encountered except in the immediate vicinity of its production. Decomposition is accelerated by contact with solid surfaces, by contact with chemical substances and by the effect of heat. |

| Incompatibilities | Ozone is a powerful oxidizing agent and reacts with all oxidizing materials, both organic and inorganic. Some reaction products are highly explosive. |

| Hazardous decomposition products | None |

Health Hazard Data

| Permissible exposure Limits | The following limits are widely accepted (USA, Sweden and other parts of Europe): 8 hours per day/5 days per week (occupational exposure limit) – 0.1 ppm 15 minutes (short term exposure limit) – 0.3 ppm |

| Toxicology of ozone | The acute and chronic effects of excessive exposure to ozone have been well investigated. Exposure to concentrations of ozone in excess of several tenths of a ppm sometime cause reports of discomfort in a small susceptible portion of the population. This can be in the form of headaches of dryness of the throat and mucous membranes of the eyes and nose following exposures of short duration. Repeated exposure to ozone at such concentrations at 24-hour intervals, however, caused no further increase in airway irritability. In fact, after the first exposures, additional exposures to ozone had progressively lesser effects suggesting that tolerance may develop over time.Ozone has been shown to be more injurious at concentrations exceeding 2.0 ppm over several hours, such as experienced by gas shielded arc welders. The primary site of acute effects is the lung which is characterized by pulmonary congestion. This acute impact subsided in welders when exposures were reduced to less than 0.2ppm. Based on animal studies, exposure over 10 to 20ppm or an hour or less believed to be lethal in humans although there has never been a single recorded fatality attributed to ozone exposure in more than 100 years of commercial use. (Compare with this experience with Chlorine as which has claimed many victims in peacetime as well as during war).

With respect to long term or chronic toxicity, ozone is a radiomimetic agent, i.e. the effects of long term exposure to excessive ozone exhibit the same effects as excessive exposure to sunlight. These effects are drying of the dermal surfaces and general ageing of exposed tissues. Ozone is not generally regarded or suspected of being a human carcinogen, neither does in exhibit teratogenic or mutagenic properties. In the event of an ozone leak:

|

| Destruering av överskottsozon | Det är accepterad praxis och lagstiftningskrav i vissa länder att ozongas inte får släppas ut i atmosfären, utan ska förstöras med hjälp av en godkänd metod för ozondestruktion (katalytisk, termisk eller absorbtion). |

| Disposal of waste ozone gas | It is accepted practice, and required by statute in some jurisdictions, that Ozone gas should not be released into the atmosphere but should be destroyed using an approved ozone destruction method (catalytic, thermal, or absorption).

|

| Exposure |

|

Ozone Tech Systems OTS AB shall not be liable for any loss or damage of any nature whatsoever, however arising, relating to the use or handling of ozone or statements contained in or omitted from this document.

Ozone Academy

Elektravägen 53

126 30 Hägersten, Sweden

TEL: +46 10 252 30 00 (Weekdays between 08.00-17.00)

www.ozone-academy.com